Rubber Linings for Propulsion Shafts

Rubber Linings for Propulsion Shafts

At our company, we line propeller shafts with rubber to prevent corrosion based on the Ministry of Land,

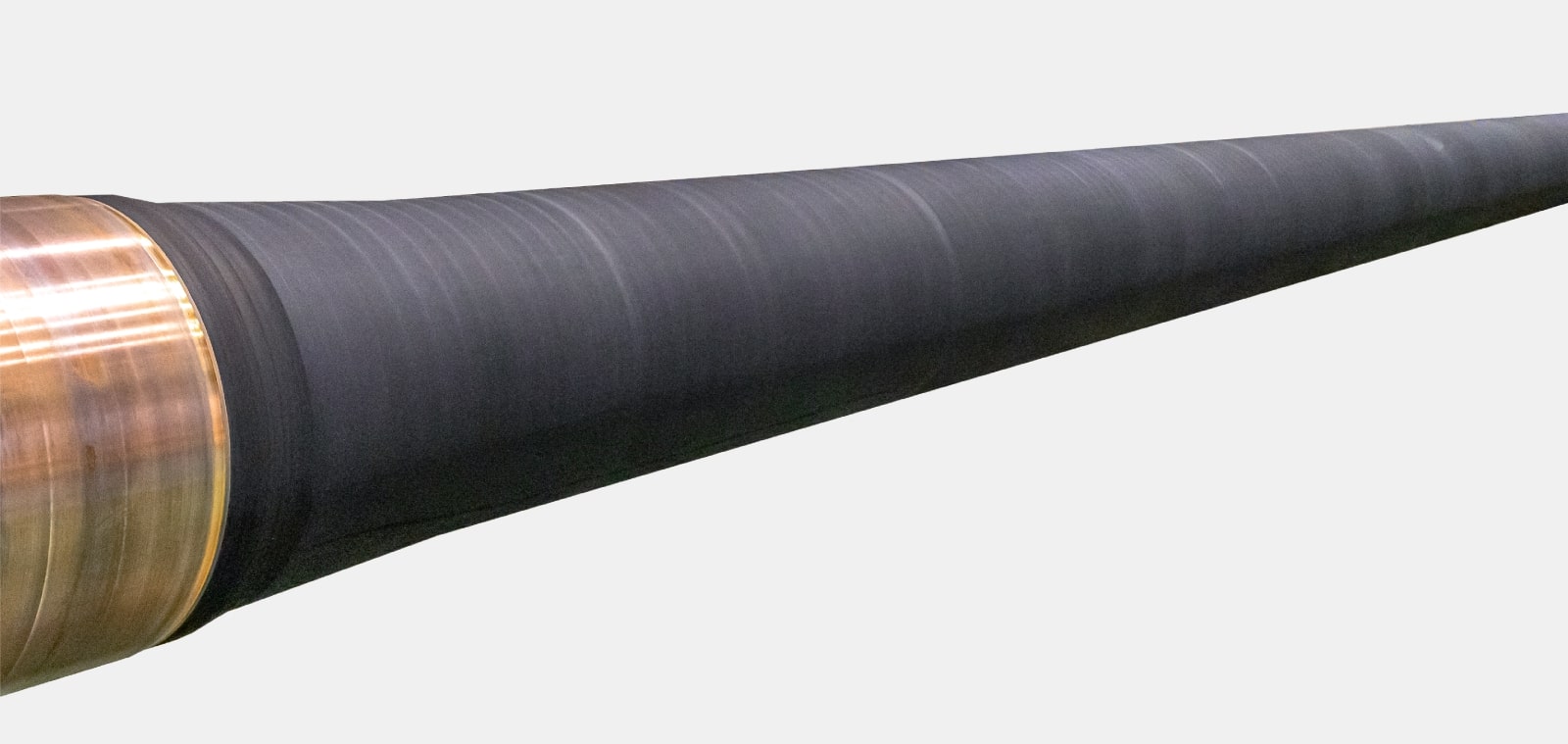

Infrastructure, and Transport’s Ship Safety Law and marine engineering regulations. Rubber linings for propeller shafts must be very strong against expansion, contraction, and torsion of the shaft due to rotational torque and temperature changes, as well as external shocks, and cannot separate easily.

Our company’s rubber linings are highly trusted products because of the structural design using ebonite on the adhesion layer, thorough quality control, and construction techniques utilizing past experience.

Main Usages of Rubber Linings for Propulsion Shafts

Ferries (large, medium, and small), fishing boats, tug boards, cargo ships, etc.

Water lubricated bearings are generally used for propulsion systems for medium and small ships, and carbon steel is usually used for the propeller shaft.

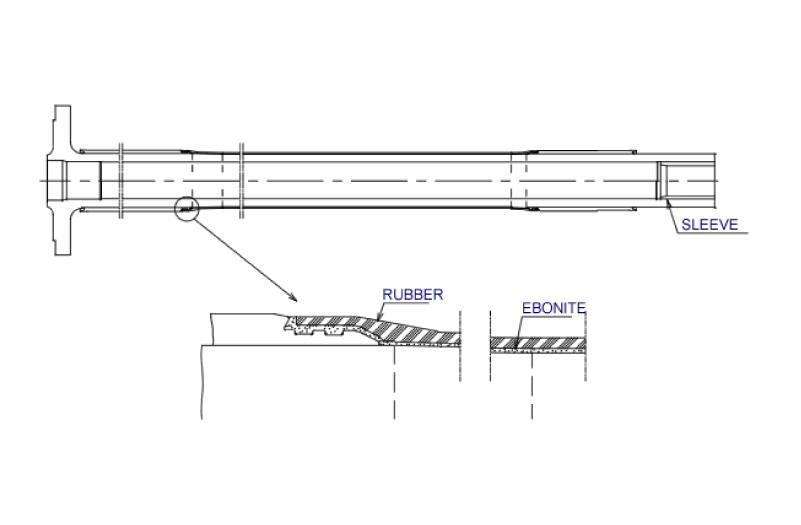

A sleeve with corrosion resistance is placed over the carbon steel bearings, but the parts that are not covered by sleeve must be covered with corrosion resistant coating according to the Ship Safety Law. At our company, we carry out rubber lining construction as a method to comply with the corrosion resistant coating.

These corrosion resistant rubber linings completely protect carbon steel from corrosion by sea water and are a highly trusted method with a track record of over 40 years.

Characteristics

The rubber linings completely prevent the permeation of sea water by wrapping extremely water resistant ebonite around the adhesion layer and using a multi-layered structure with strong natural rubber to absorb external shocks on the surface.

In addition, they have enough adhesion and elasticity to sufficiently withstand the bending and twisting of the propeller shaft while sailing.