Water Lubricated Bearings (MR-Bearing)

Type approval received for each ship classification

Water Lubricated Bearings

(MR-Bearing)

Bearings for propeller shaft systems for ships can be broadly classified into water lubrication and oil lubrication. In the past, lignum vitae, which is a natural wood containing resin, had been used for water lubricated bearings. However, the depletion of raw wood in the production areas (Central and South America) has made it difficult to obtain materials with good quality, resulting in the frequent occurrence of irregular wear and swelling. In recent years, rubber bearings with stable quality are most commonly used instead of lignum vitae. At our company, we began developing rubber bearings in the early 1970s. We provide excellent rubber bearings that are strong and stable in the long-term by using rubber that has great sliding properties and wear resistance, as well as a special method for adhesion with the metal shell. At present, we have numerous achievements.

Characteristics of Water Lubricated Bearings (MR-Bearing)

-

No Damage to the Shaft and Sleeve

Even if sand or pebbles fall between the shaft and the rubber bearings, the lubricating water expels the debris along the ridge as the shaft rotates. At out company, we implement designs with rubber that take advantage of these properties.

-

Low Power Loss

In general, wet rubber and metals have properties of sliding very well. At our company, we pay attention to these characteristics and implement designs with rubber that have a low coefficient of friction.

-

Low Wear

Wear resistance is better compared to lignum vitae. There is an example of rubber bearings being used for over 10 years in a situation where lignum vitae had to be replaced every several months.

-

Swelling resistance

We use a rubber with excellent swelling resistance that does not cause hydrolysis.

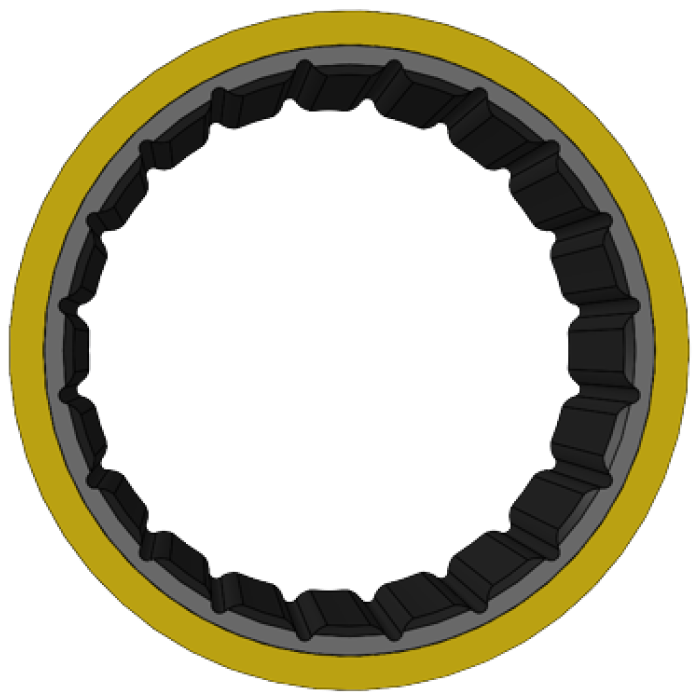

Structure

This is the type that is generally widely used. Rubber is vulcanized to adhere to the inside of the metal shell, and there are a certain number of ridges carved into the rubber so that lubricating water can be passed through for usage.

Full Mold Type

Basic Technical Info

| Type | Size Capability, I.D. (mm) |

Materials | Split Version |

Typical L/D Ratio |

Normal Allowable Pressure (MPa) |

Installation |

|---|---|---|---|---|---|---|

| MRB | 15 - 650 | Copper Alloy (Brass, Bronz) Bakelite |

Available | 4 | 0.25 | Press fit Clearance fit |

Introduction Example

Haeyang Metal, Silla Metal, Baeksan Machinery, Daesun Shipbuilding, etc.