Rubber Rolls

Rubber Rolls

Rubber rolls for steel products and paper manufacturing are used under adverse conditions involving loads, heat, chemicals, and oils.

At our company, we have earned a high degree of trust from users through our unique methods, such as rubber compounding techniques, molding methods, and vulcanizing methods.

We provide various types of rubber rolls, such as ringer rolls, bridle rolls, and sink rolls, that are used in cold rolling lines at iron mills. Our company’s strengths include the ability to provide reliable products with few internal flaws through the joint use of ribbon molding machines and high pressure heated water vulcanization.

The revolutionary AW series is an excellent rubber material that can be used even under adverse conditions, with chemical resistance, abrasion resistance, and oil resistance that exceed previous materials.

Main Usages of Rubber Rolls

Ringer rolls, bridle rolls, deflector rolls, dam rolls, pinch rolls, support rolls, etc.

Our company’s rubber rolls are mainly used in cold rolling lines at iron mills.

Cold rolling lines at iron mills consecutively acid clean, degrease, anneal, and plate coils. Rubber rolls are used at various points of these lines to pull iron plates, squeeze out liquids, and change directions.

Our company’s rubber rolls are also used at paper manufacturing factories.

Rubber Material List

Specialty Rubber

| Rubber Material | AWC972 | AWC982 | NWZ982 | ALC172 | CR-6 | CPW781 | LMY90 | LMX7855 |

|---|---|---|---|---|---|---|---|---|

| Polymer Type | H-NBR | Chlorine-based | CPE | Polyurethane | ||||

| Hardness(Shore A) | 70 | 80 | 85 | 70 | 90 | 85 | ||

| Tensile Strength(kgf/㎠) | 298 | 291 | 297 | 230 | 450 | 420 | ||

| Elongation(%) | 370 | 324 | 280 | 260 | 420 | 450 | ||

| Resilience(%) | 42 | 41 | 33 | - | 55 | 40 | ||

| Permanent Set(%) | - | 55 | ||||||

| Taber Abrasion(㎤) | 0.007 | 0.175 | ||||||

| Tear Strength(kgf/㎠) | 26.4 | 29.6 | 36.9 | - | 92 | 94 | ||

| Color | Black | Black | Black | Black | Black | White | White | Amber |

| Water Resistance | ◎ | ◎ | ◎ | ○ | ◎ | ○ | ||

| Oil Resistance | ◎ | ◎ | ◎ | ◎ | ○~△ | ○~△ | ||

| Resistance to Hydrochloric and Sulfuric Acid |

◎ | ◎ | - | △~○ | ◎ | ○ | ◎ | |

| Resistance to |

◎ | - | - | |||||

| Resistance to |

- | - | - | - | ||||

| Ambient Temperature(℃) | 100 | 100 | 130 | |||||

| Maximum Temperature(℃) | 130 | 130 | 150 | |||||

General Purpose Rubber

| Rubber Material | NN572 | NN572-Hard | NSB721 | NSB820 | CPB782 | TE205 | CRM672 |

|---|---|---|---|---|---|---|---|

| Polymer Type | CSM | NBR | CPE | EPT | Specialty | ||

| Hardness(Shore A) | 70 | 75 | 73 | 80 | 80 | 77 | 75 |

| Tensile Strength(kgf/㎠) | 202 | 180 | 200 | 205 | 230 | 130 | 190 |

| Elongation(%) | 350 | 375 | 350 | 392 | 170 | 300 | 300 |

| Resilience(%) | 39 | 38 | 30 | 30 | 30 | 44 | 30 |

| Permanent Set(%) | 3 | - | 5 | - | - | 7 | - |

| Taber Abrasion(㎤) | 0.045 | 0.116 | 0.095 | 0.06 | |||

| Tear Strength(kgf/㎠) | 45 | 52 | 40 | - | 25 | 35 | 30 |

| Color | Black | Black | Black | Black | Black | Black | Black |

| Water Resistance | ○ | ○ | ◎ | ◎ | ○ | ◎ | ◎ |

| Oil Resistance | △ | △ | ◎ | ○ | ○ | ✕ | ✕ |

| Resistance to Hydrochloric and Sulfuric Acid |

○ | ○ | ○ | ○ | ◎ | ◎ | ◎ |

| Resistance to Caustic Soda | ○ | ○ | - | - | ◎ | - | ◎ |

| Resistance to Chromic Acid | ✕ | ✕ | ✕ | ✕ | ○ | - | ○ |

| Ambient Temperature(℃) | 90 | 90 | 90 | 90 | 120 | 120 | 130 |

| Maximum Temperature(℃) | 120 | 120 | 120 | 120 | 140 | 140 | 150 |

Polyurethane

| Rubber Material | G-7964 | C-7924 | NT-7904 | N2-7905 | J-7955 | J-7904 |

|---|---|---|---|---|---|---|

| Polymer Type | Ether | Ester | ||||

| Hardness(Shore A) | 94 | 92 | 90 | 90 | 95 | 87 |

| Tensile Strength(kgf/㎠) | 550 | 450 | 600 | 405 | 455 | 450 |

| Elongation(%) | 400 | 450 | 400 | 460 | 460 | 450 |

| Resilience(%) | 25 | 33 | 25 | 55 | 28 | 36 |

| Permanent Set(%) | 5 | 2.5 | 2 | 27 | 50 | 2 |

| Taber Abrasion(㎤) | 0.009 | - | 0.011 | 0.01 | 0.021 | 0.021 |

| Tear Strength(kgf/㎠) | - | - | - | 89 | 122 | - |

| Color | Green | Green | Green | Amber | Amber | Green |

| Water Resistance | ○ | ○ | ○ | ○ | △~✕ | △ |

| Oil Resistance | △ | △ | △ | △ | ◎ | ○ |

| Resistance to Hydrochloric and Sulfuric Acid |

○ | ○ | ○ | ○ | ✕ | △ |

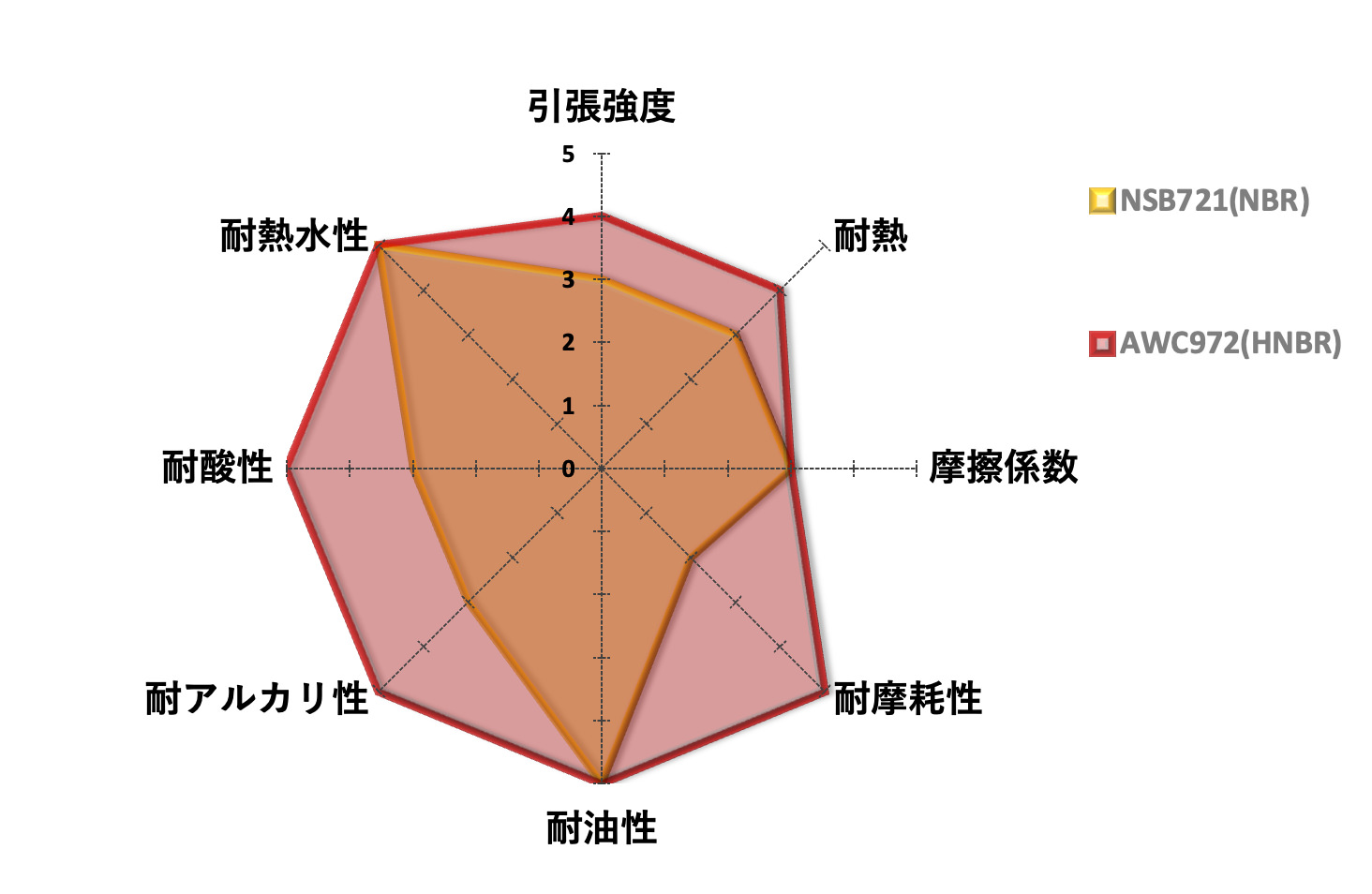

AWC

A versatile specialty rubber roll with excellent acid resistance, alkali resistance, oil resistance, and abrasion resistance.

Recommended Line/Roll

We have adopted the following lines and rolls, achieving an extension of the replacement cycle.

Lines: PL, CGL, CAL

Rolls: Linger Rolls, Auto Wide Linger Rolls, Sync Rolls, etc.

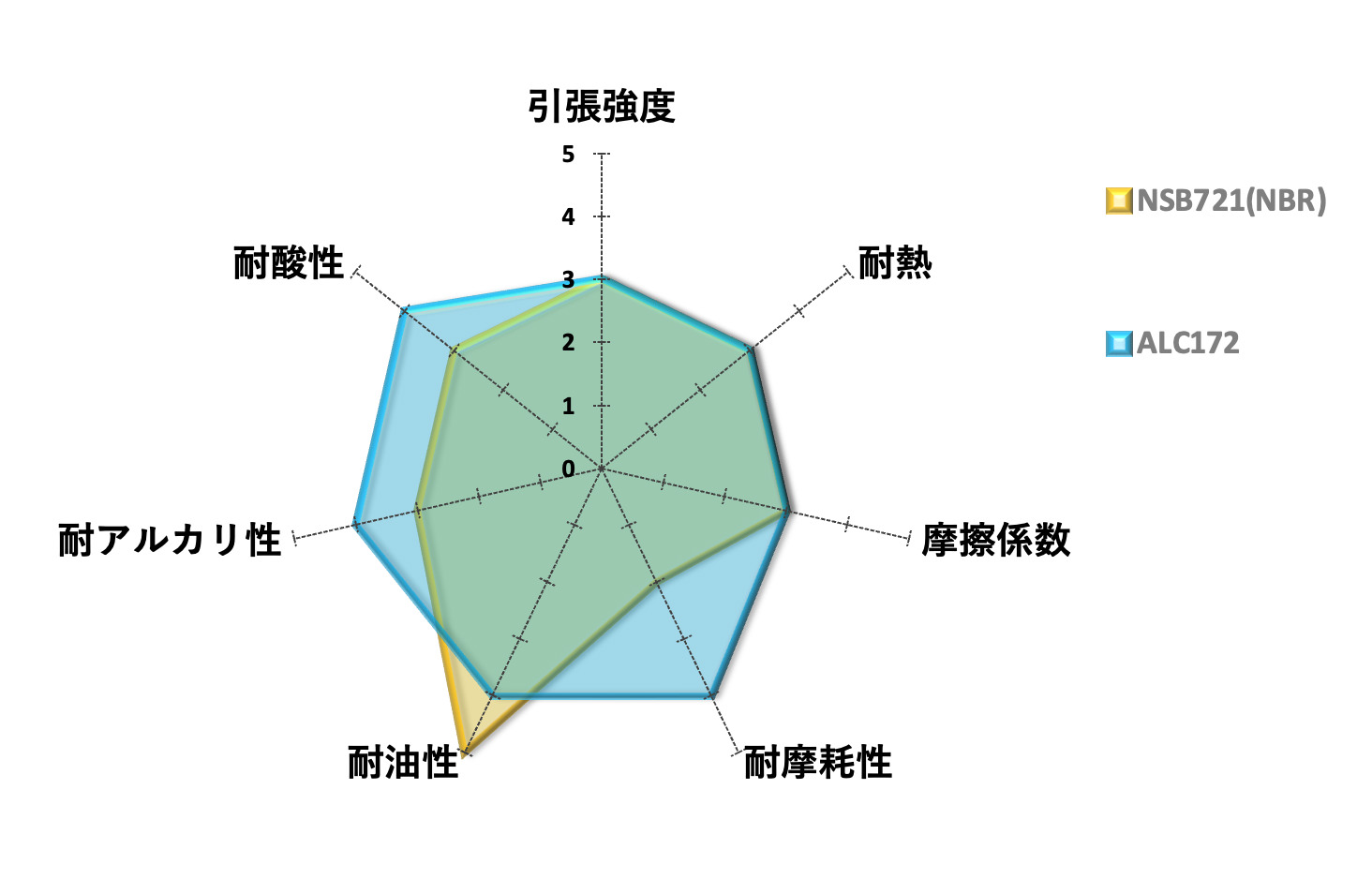

ALC

Special synthetic rubber roll with a balanced combination of alkali resistance and oil resistance.

Recommended Line/Roll

We have adopted the following lines and rolls, achieving an extension of the replacement cycle.

Lines: CGL, EGL

Rolls: Linger Rolls, Dam Rolls, Support Rolls, etc.

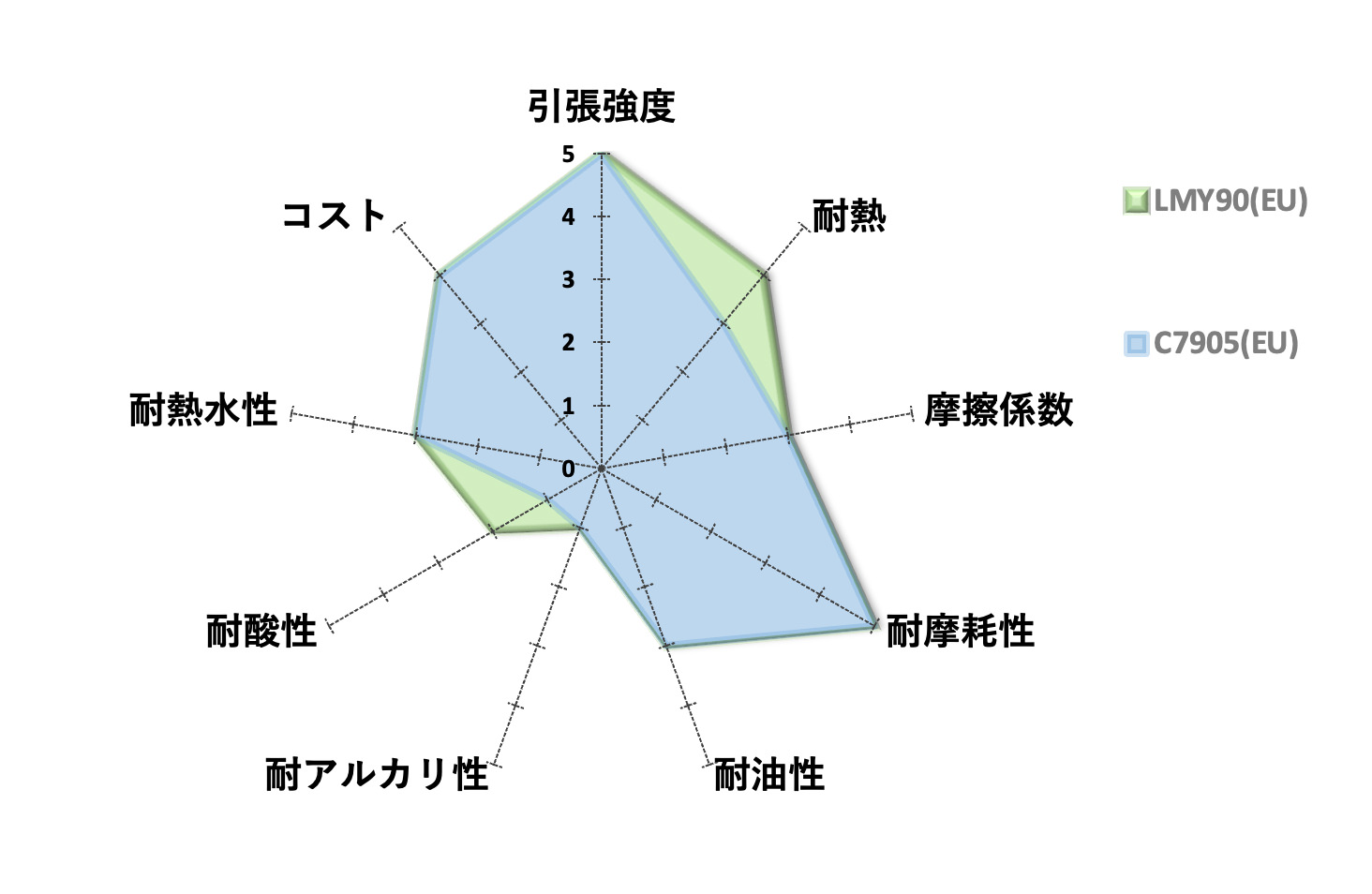

LMY

Improved ether-based polyurethane rubber roll with wear resistance and resistance to hydrolysis properties.

Recommended Line/Roll

We have adopted the following lines and rolls, achieving an extension of the replacement cycle.

Line: PL

Rolls: Linger Rolls, Swing Rolls, Snubber Rolls, etc.

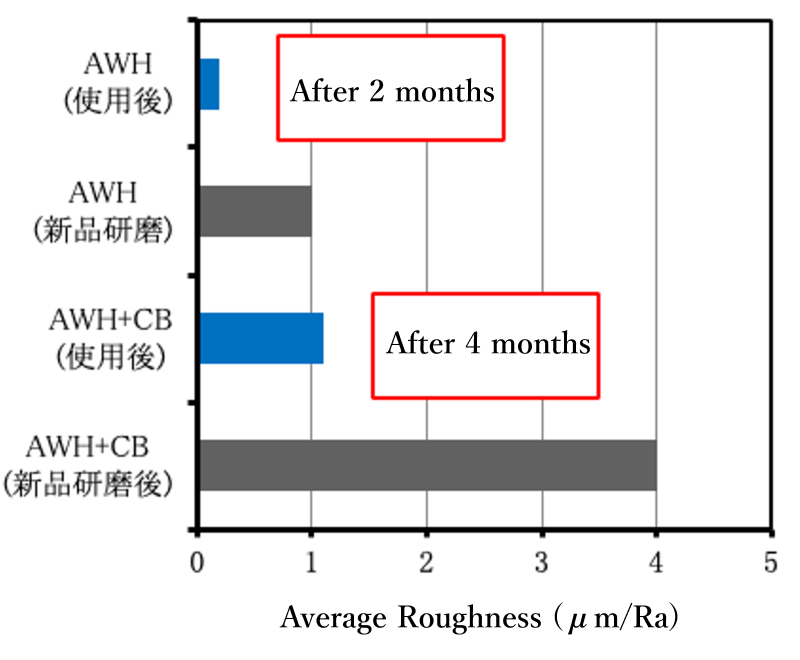

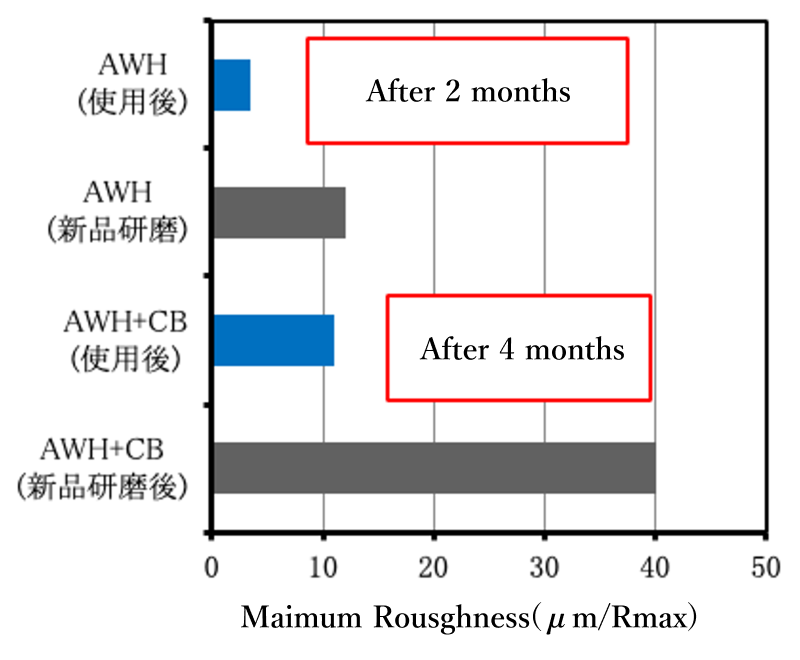

Ceramic Balloon

Enhanced grip strength is achieved by incorporating specialty synthetic rubber alongside general-purpose rubber rolls.

Introduction Example

Nippon Steel Corporation, Yahata Works (Kitakyushu) / Nippon Steel Corporation, Oita Works / Nippon Steel Corporation, Hanshin Works (Toyo) / Nippon Steel Corporation, Hirohata Works / Nippon Steel Corporation, Nagoya Works / Nippon Steel Corporation, Kimitsu Works / Nippon Steel Corporation, Kashima Works / Nippon Steel Stainless Steel Corporation, Kashima Plant / Nippon Steel Stainless Steel Corporation, Yamaguchi Plant (Shunan Area) / Nippon Steel Stainless Steel Corporation, Yamaguchi Plant (Hikari Area) / JFE Steel Corporation, Fukuyama Works / JFE Steel Corporation, Kurashiki Works / JFE Steel Corporation, Chiba Works / Kobe Steel, Ltd., Kakogawa Works / Yodogawa Steel Works, Kure Plant / Toyo Kohan Co., Ltd., Shimotsu Business Unit Primetals Technologies Japan Corporation / Mitsubishi Chemical Corporation / Nippon Paper Industries Co., Ltd., Iwakuni Mill / Tata Steel Limited / JSW Steel Limited / ArcelorMittal Ghent