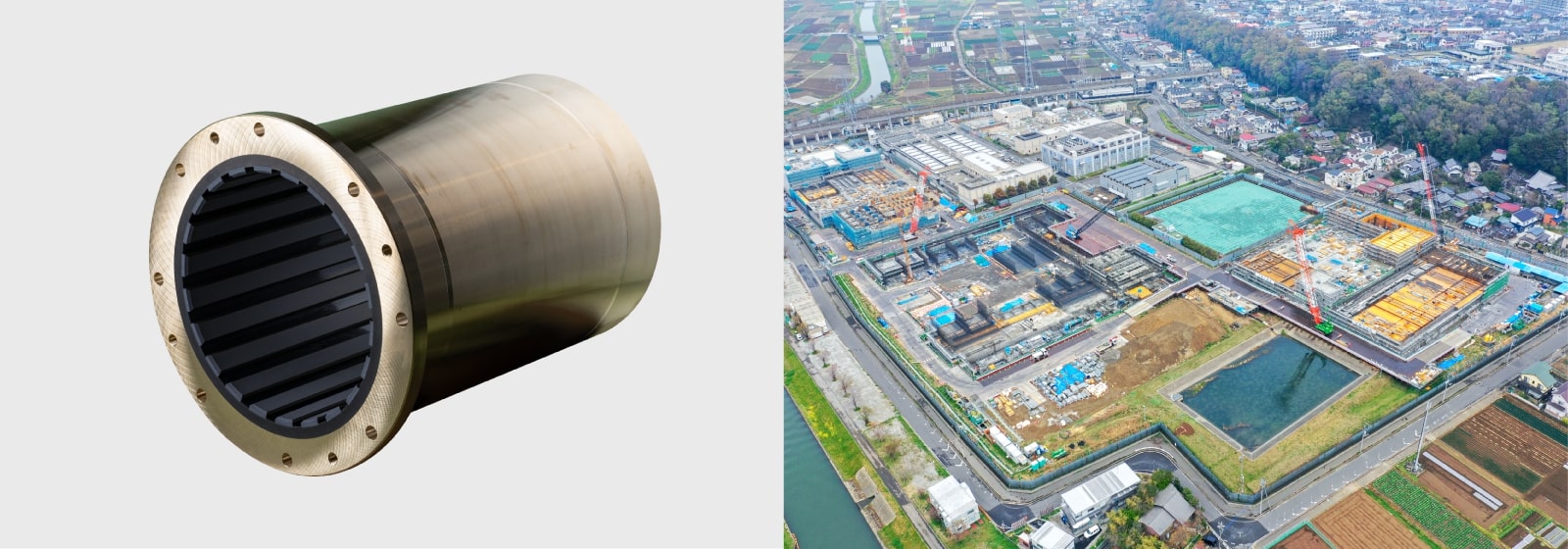

FF-Bearing for Pumps

FF-Bearing for Pumps

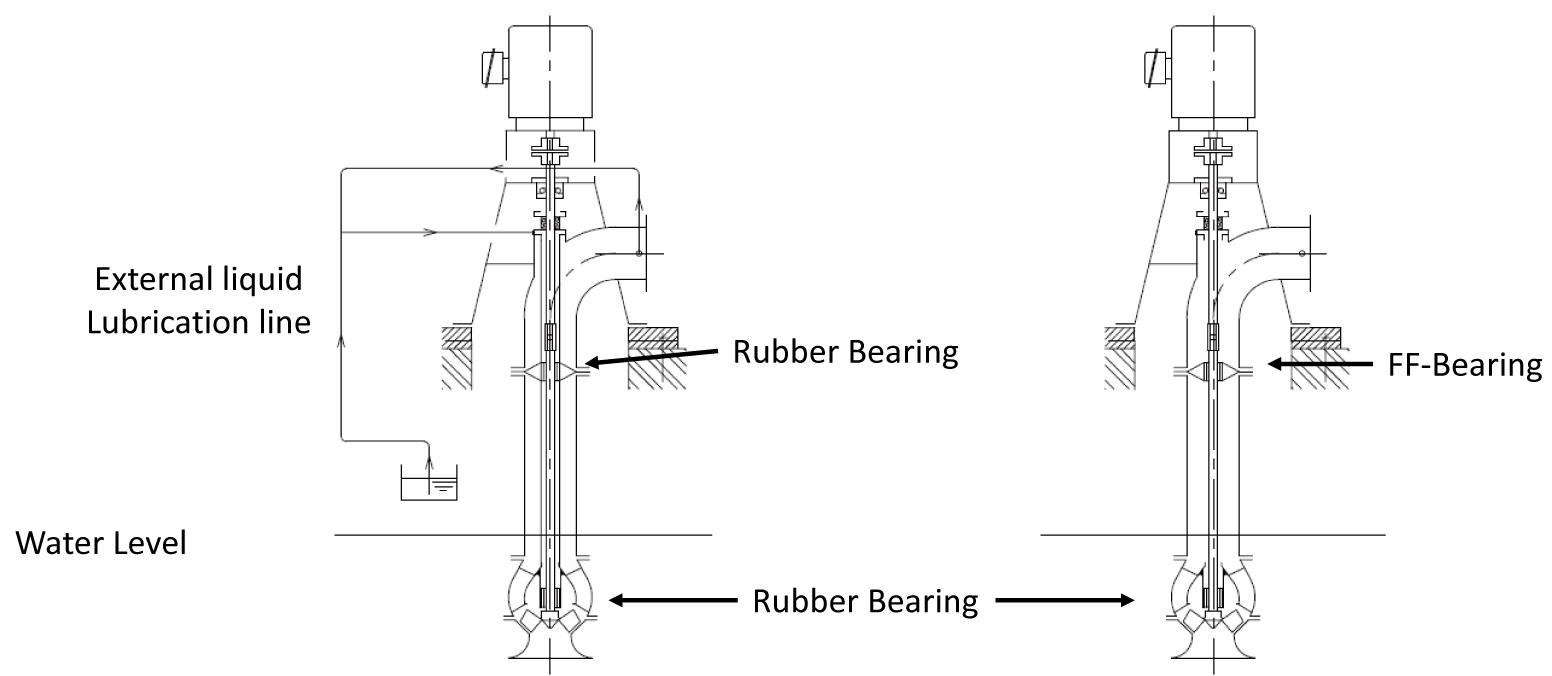

Although they do not allow start-up without injecting water, these submerged bearings are the most stable if there is water prior to start-up. These bearings can be provided at a lower cost compared to FF-Bearing. They have produced steady results, as they have been used for long periods in pumps with high specifications at thermal and nuclear power plants.

Main Usages of FF-Bearing for Pumps

Circulating water pumps for nuclear and thermal power plants, machine cooling seawater pumps, screen wash pumps, desalination plants, flood control pumps, water and sewage intake and drainage pumps, agricultural water pumps, etc.

Plants by Purpose

Water and sewage, Thermal power generation, IWPP (Saline water conversion), Geothermal power generation, Gas storage system, Nuclear power plant, Petrochemical complex, Agricultural water / River water intake, Hydropower

Installation of Dry-Start Pump

Characteristics of FF-Bearing for Pumps

-

Excellent sliding property

To enable dry start in a safe condition

-

High wear resistance Low aggression on sleeves

To maintain clearance for a long period

-

Excellent damping property

To suppress pump abnormal vibration

-

Self-alignment capability

To decrease load by deflected contact

Introduction Example

TSURUMI MANUFACTURING CO., LTD. / ANDRITZ / ISHIGAKI COMPANY, LTD. / Kubota Corporation / SHINKO IND.LTD. / Shin Nippon Machinery Co., Ltd. / SHINRYO KOUGYO Co., Ltd. / TAIKO KIKAI INDUSTRIES CO., LTD. / TORISHIMA PUMP MFG.CO.,LTD. / MITSUI MIIKE MACHINERY CO.,LTD. / Mitsubishi Heavy Industries, Ltd. Takasago Manufacturing / DMW Corporation / EBARA CORPORATION / HONDA PUMPS Co., Ltd. / Hitachi Industrial Products Co., Ltd. / JPEC Co., Ltd. / Maruhachi Pump Manufacturing Co., Ltd. / Electric Power Development Co.,Ltd., etc.