Water Lubricated Bearings

(FF-Bearing)

Type approval received for each ship classification

Water Lubricated Bearings

(FF-Bearing)

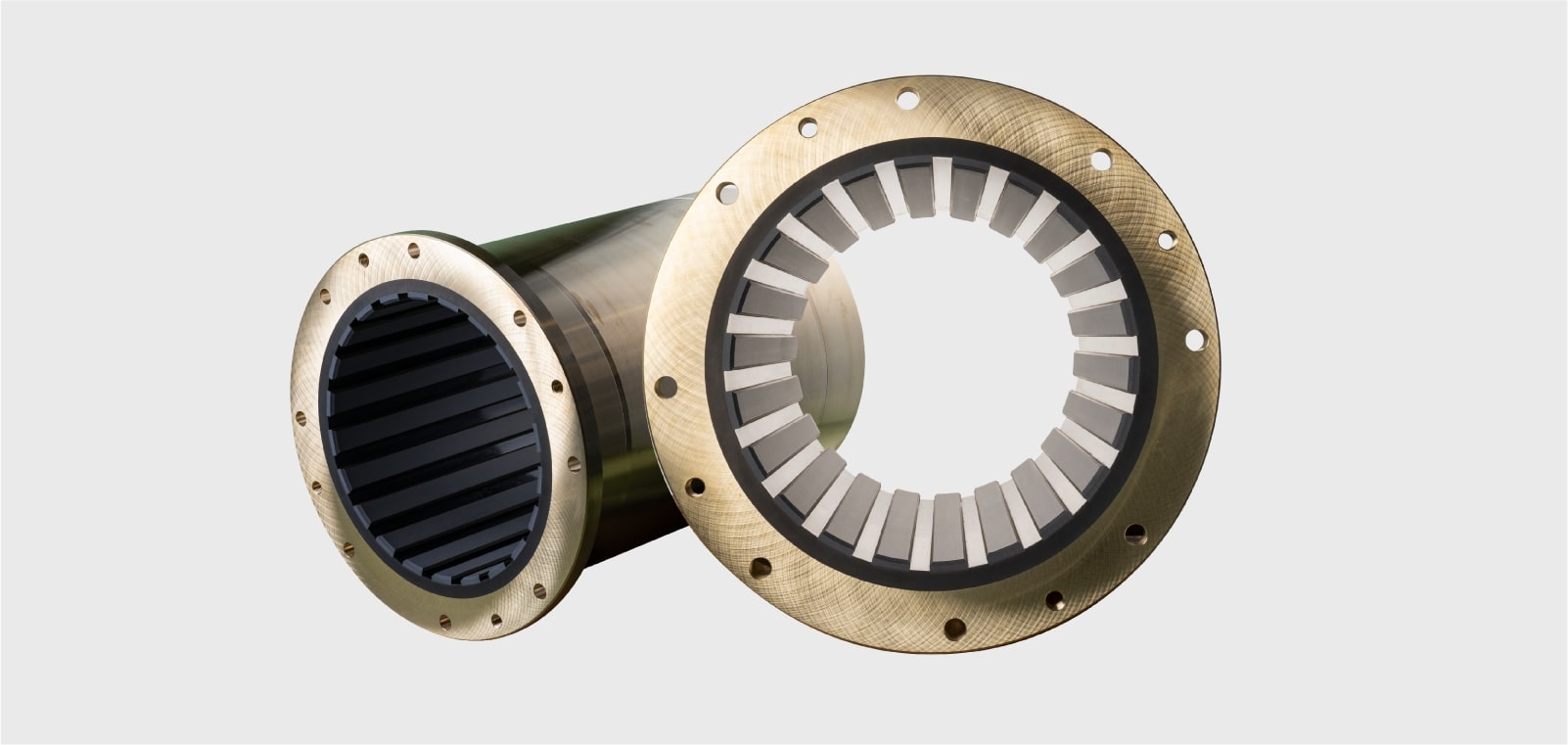

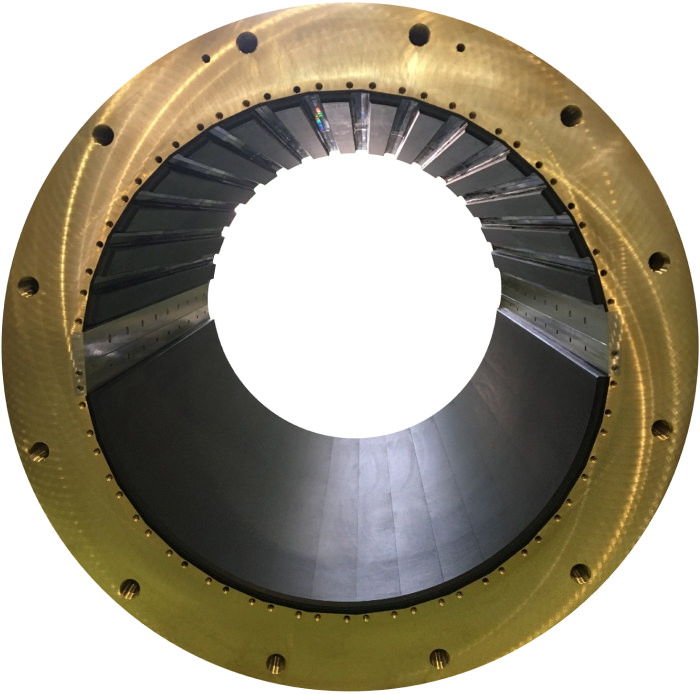

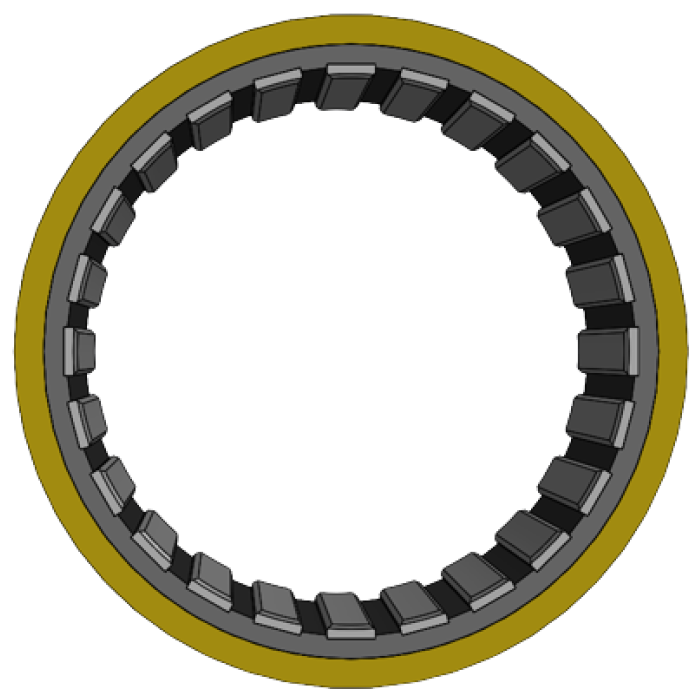

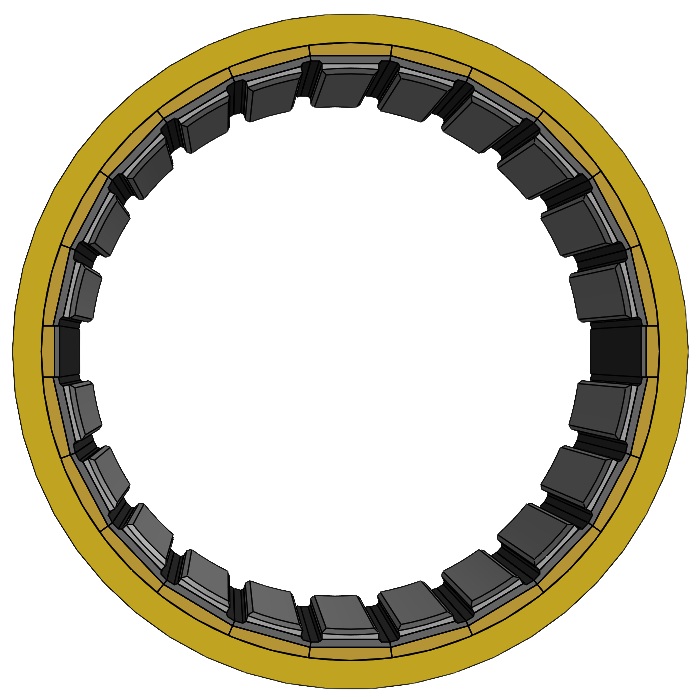

FF-Bearing is a three-layer bearing with rubber and tetrafluoroethylene inside the outer cylinder.

FF-Bearing takes advantage of the elasticity that is a feature of rubber bearings, and uses slippery polytetrafluoroethylene on the sliding surface. Compared to conventional rubber bearings, FF-Bearing has ⅛ the frictional resistance and reduces energy loss. This bearing significantly reduces fuel consumption and contributes to reducing CO2, the main cause of global warming.

In addition, the bearings are four times more abrasion-resistant than rubber bearings and contribute greatly to the global environment in terms of resource depletion.

In 2019, we launched FF-Bearing CR (patented), which maximizes low-friction performance by eliminating the water groove on the sliding surface.

Characteristics of Water Lubricated Bearings (FF-Bearing)

-

Lower Fuel Consumption

The friction coefficient is extremely low, approximately 1/8th of that of conventional rubber bearings, resulting in significantly reduced energy loss and an expected energy-saving effect. For detailed data, please feel free to contact us.

-

Resistance to Seizure:

The low friction coefficient minimizes heat generation in sliding parts, making it less prone to seizure even with reduced seawater intake. Coolant requirements can also be set at a lower level compared to conventional rubber bearings.

-

Quietness

With inherent self-lubrication and excellent friction characteristics at low rotational speeds, it effectively suppresses stick-slip phenomena during startup and shutdown. This feature results in extremely minimal noise generation, a common occurrence in rubber bearings.

-

History and Reference:

FF-Bearing was developed in 1981, and to date, it has a cumulative delivery record of over 700 vessels. With a long history and numerous successful adoptions, the technology and experience, enriched by abundant data and continuous improvements, provide confidence for safe usage.

-

Suitable for Large Vessels:

Its self-lubricating properties, coupled with a moderate softness even under high loads, enable the realization of self-alignment. It can be applied to large vessels operating under substantial weight conditions. The largest delivered size by our company is in the Antarctic observation ship "Shirase," with a bearing inner diameter of φ810.

Differences Between Water Lubricated Bearings and Oil Lubricated Bearings

Please feel free to contact us for details and test data.

Industrial Products Sales Department:info@mikasa-industry.com

Structure

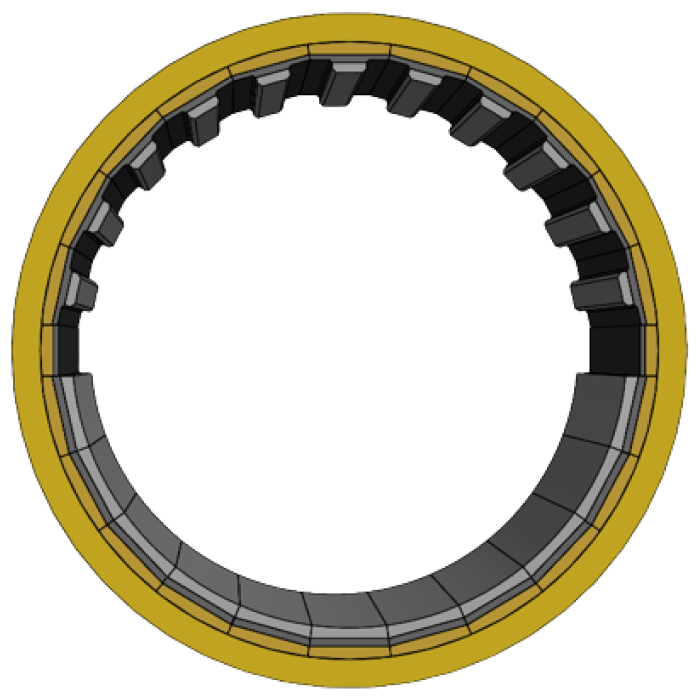

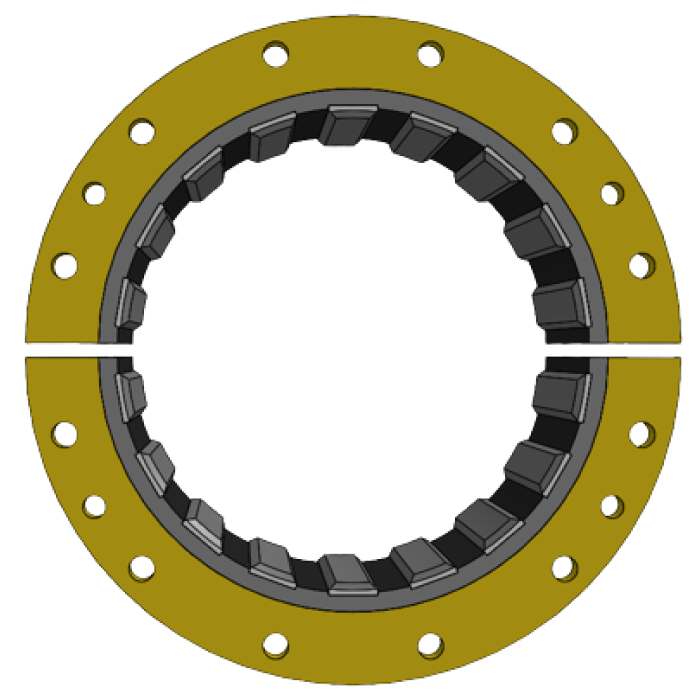

FF-Bearing have a shape in which a layer of soft rubber is sandwiched between the shell (outer casing) and the special polytetrafluoroethylene.(Crescent type is patented)

The sliding member was selected as a result of long-term comparative testing of various materials and produces excellent results as material for submerged bearings. Additionally, the soft rubber layer has an appropriate amount of elasticity to effectively ease the occurrence of high localized surface pressure due to one-sided contact of the bearing surface.

Various types are available to suit different mounting methods and sizes. Please feel free to contact us for more details.

Full Mold Type

Barrel Type

Crescent Type

Split Type

Basic Technical Info

| Type | Size Capability, I.D. (mm) |

Materials | Split Version |

Typical L/D Ratio |

Normal Allowable Pressure (MPa) |

Installation |

|---|---|---|---|---|---|---|

| FFB | 30 - 1000 | Copper Alloy (Brass, Bronz) Bakelite |

Available | 2 | 0.6 | Press fit Clearance fit |

Introduction Example

Schottel, Andritz Hydro, Navship, Hyundai Mipo, Chantiers de l'Atlantique, etc.