Characteristics of Mikasa’a Industrial Products

Mikasa’s Undoubtable Techniques Are Supported by History and People

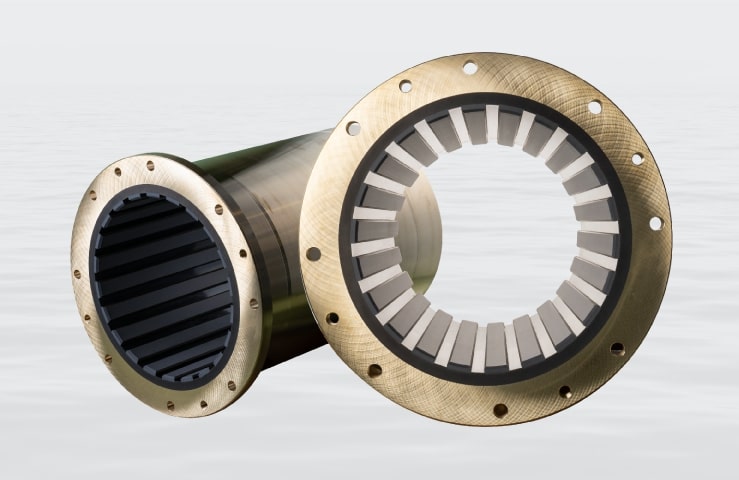

Mikasa’s principal industrial products include submerged bearings that are used for pumps used on ships and on land, rubber linings for propulsion shafts on ships, and rubber rolls used on manufacturing lines for steel products, paper manufacturing, and resin plates.

We produce unique products that are used around the world, and our products are seen as the standard in certain fields thanks to the high technical abilities that have been inherited and our corporate culture of earnestly responding to requests. We will continue to aim to manufacture products that fulfill our customers’ needs.

A History of Inherited Techniques

Since being founded, Mikasa has strived to manufacture rubber products. The rubber roll for newspaper printing lines that Marusan Gomu Industries, 1 of the 3 companies that are part of the roots of Mikasa, received an order for in 1937 can be considered the first of our industrial products. During the post-war revival and high growth periods, the demand for rubber products grew, and we began to manufacture and supply rubber products in various fields.

Then, we expanded into submerged bearings for ships and pumps and propulsion shaft rubber linings for ships using the know-how that we had accumulated. The technical abilities that we have continuously inherited from the past continue to be polished while adapting to the changing times.

Trusted Technical Abilities

Our water lubricated bearings are of the largest scale in Japan and were used on Shirase, the Ministry of Education, Culture, Sports, Science and Technology’s Antarctic exploration ship. Our uniquely developed water lubricated FF-Bearing can also be used on large ships. Our rubber linings for propeller shafts support a maximum size of 20m, making us the only company in Japan to be able to do so, and are equipped with strong adhesion and elasticity.

Our rubber rolls for factory lines withstand various adverse conditions required for each product, such as heavy loads, heat, and chemicals. All of the above are produced using our high technical abilities that we have developed over many years, such as rubber mixing technologies, molding methods, and adhesion to metals.

Meticulous Development and Response Capabilities

Submerged bearings that are used for pumps used on ships and on land, rubber linings for propulsion shafts on ships, and rubber rolls used on manufacturing lines for factory manufacturing lines are all close to “one of a kind” items that have been developed based on the scale and requirements of each ship and facility. What is demanded of us, such as improved performance based on each environment and improved longevity and durability, is constantly increasing. We have received more and more requests from overseas in recent years and we respond to each request with meticulous development and response capabilities.

Our products are produced using our high technical abilities that we have developed over many years, such as rubber mixing technologies, molding methods, and adhesion to metals.

Environmentally Friendly Product Manufacturing

Moving forward, there is no doubt that environmental consideration will become more important. Because all of the bearings for ships, which are our company’s main product, that we produce use water as their lubricant, they are seen as being more environmentally friendly than standard products that use oil as their lubricant and are used on many ships. Furthermore, we are able to support large ships through our development of FF-Bearing that produce results even under heavy loads and will continue to product products that are friendly to the Earth, while also considering improvements for fuel consumption by improving lubrication performance.

Source: Maritime Self Defense Forces Homepage